“Are you aware that I am rubber, and you are glue, and whatever you say to me bounces off, of me, and sticks to you? So put that in your, back pocket.”

~ Mary Katherine Gallagher (SNL):

The Big Bang Theory (2007)

[Leonard’s mother Beverly, a neuroscientist and psychiatrist, is visiting]

Sheldon Cooper: Your mother is brilliant, analytical, insightful – and I’m betting she never hit you with a Bible because you wouldn’t eat your Brussels sprouts.

Leonard Hofstadter: Sheldon, you don’t give your mother enough credit. She’s warm, she’s loving, she doesn’t glue electrodes to your head to measure your brain waves while potty training…

Sheldon Cooper: You were lucky! When I was a kid, if I wanted an EEG, I had to attach my own electrodes.

~

Looks like I picked the wrong week to quit sniffing glue.

Lloyd Bridges as Steve McCroskey , Airplane

~

Glue… very powerful stuff.

The Blues Brothers

Have you ever gotten knee deep in designing your rebar embedment depth with an epoxy when you realize that something’s just not right? You’re using the manufacturer’s technical information but the calculations don’t seem to work or seem unconservative? Let’s go back in time a little bit.

Back in the 1960’s a new way to design anchors in concrete after it had hardened had been developed. A Post-Installed Anchor (PIA) manufacturer came up with fast curing adhesives that could be used for doweling rebar. The adhesives were either pure epoxies, which are like glue, or hybrid adhesives, which are more like a mortar or paste. The technology and research for these adhesives are based on “anchor theory” which is great, but it has a few short comings. It is based on relatively shallow embedments and primarily deals with unreinforced concrete. But what happens when you’re doweling rebar? The current design code for post installed anchors only covers anchors embedded up to a maximum of 20xD or 25” (see ACI 318, Appendix D). This limits you to 12.5” for a #5 rebar… but a lap splice is usually longer than that… And what happens when you anchor into a column or pedestal? Edge distances become an issue in your calculations and what about the benefit to using stirrups and transverse reinforcement? How are you supposed to design this now?

Where you go now is back to rebar development length from good old ACI 318. What the anchor researchers found is after you get to a certain depth, your anchors behave differently. You’re less likely to have a concrete failure and more likely to have a steel failure. Development length of rebar in ACI 318 is based on yield strength and can lead to greater depths than anchor theory gives you. So how deep do you have to set that rebar in the concrete anyway? Let’s take a quick look at ACI 318-08, Chapter 12 for tension reinforcement…

The basic development length equation from Chapter 12 is:

Now let’s make a couple of assumptions:

f’c = 3,000 psi, fy=60,000 psi, db =#5 (5/8”), c = cover = 3”, rebar spacing = 6”, Ktr

(transverse reinf.) = 0,

Yt = 1.3 (more than 12” concrete below horizontal reinforcement), Ye = 1.0 (uncoated reinforcement), Ys = 0.8 (No. 6 bar or smaller), l = 1.0 (normal wt. conc.),

while (c+Ktr)/db < 2.5 & Yt *Ye<1.7.

A little math… (C+Ktr)/db = (3+0)/0.625 = 4.8 > 2.5, therefore use 2.5

Yt *Ye=1.3 < 1.7, therefore use 1.3.

Therefore, ld = 21.4”.

That is for rebar cast into concrete. Now let’s look at doweling with adhesives. What is the equation for yield strength of a rebar?

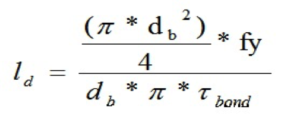

And the equation for bond strength?

What is the depth/length required to develop the yield strength of the rebar? Setting Fy=Fb and solving for ld we get:

So what are we missing? Oh yeah, the bond strength, tbond. This is where it gets a little tricky. What is the bond strength of an adhesive? And what adhesive are you going to use? Nowadays the easiest place to find information about an adhesive is the Evaluation Services Report or ESR. This report can be found on the International Code Council’s (ICC’s) website http://www.icc-es.org/reports/index.cfm?search=search. If we look at Hilti’s HY-150MAX adhesive for #5 rebar at temperature range A, tbond = 1,296 psi (assuming the hole is the right size, it has been cleaned properly, etc.). So what is the depth of embedment required to develop the rebar yield strength?

For your design you would use the more conservative development length of 21.4”. BTW – this means that the bond strength used in the development length equation in Chapter 12 is less than the bond strength used in this example. The bond strength of a rebar embedded 21.4” with HY 150MAX is 54,456 lbs! (p*db*tbond *ld) which obviously will not be your failure mode. Please note that development length may not always control. Higher concrete strengths will reduce the development length per the ACI equation. For extra credit you can set ld for yield strength equal to ld from ACI 318 Chapter 12 and see exactly what bond strength is used… I know some of you will ;o)

Please note that your work is not done here. There are more checks throughout ACI 318-08 that need to be performed before you put your stamp on this. You may yet need to check for concrete breakout/anchor failure depending on your application. Ask yourself, are your rebar going into a pedestal, a column, top of wall or in a footing? Are your rebar in the tension or compression or in the positive or negative moment regions? There are many variables, so be careful and have someone back-check your work! For those of you that made it to the end of this article and have never gone down this path before, I thank you for your patience. Hopefully this article helps turn the light on and you can now see the rest of the way.

Happy Anchoring!

Brian Clarke, PE